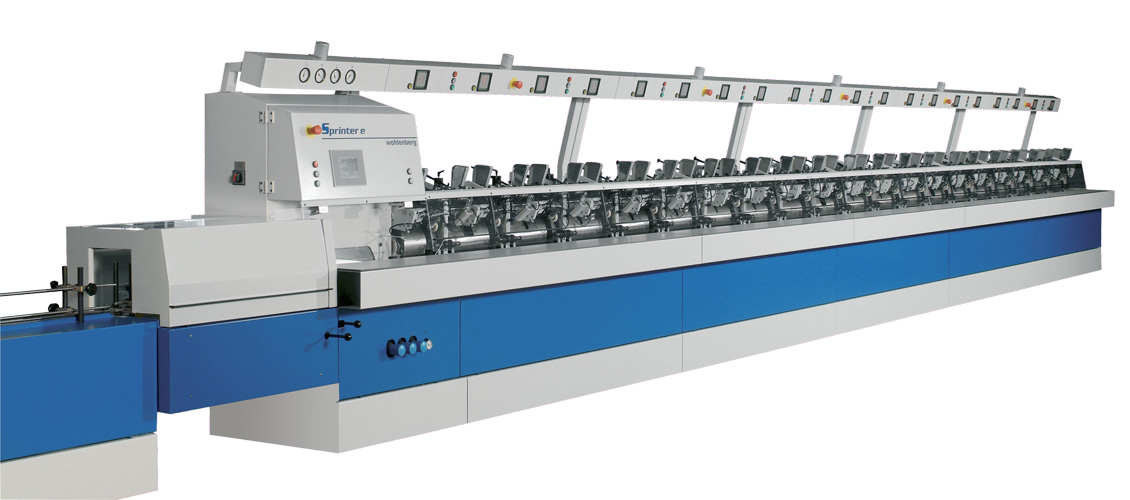

Sprinter

The reliable gathering machine

The Sprinter gathering machines are designed based on the modular concept. All elements can be combined individually and used both as stand-alone machines or inline with a perfect binder. The machine's low height, clearly laid out arrangement and functional design represent a visible expression of modern mechanical engineering, always with an eye on technical safety and reliability aspects.

The Winjector is a new, compact and patented suction pump system for optimized vacuum generation. Based on the multi-stage ejector technology (Coax®-Technology) vacuum is locally generated from compressed air. Its compact design allows the use in the various stations of the gathering machine Sprinter i.e. each station has two decoupled Winjectors creating a vacuum where it is needed.

This new technology also offers the advantage that the vacuum can be controlled individually in its strength and the sheet is separated by a blow-off specifically from the sucker. This increases process reliability and productivity. The elimination of conventional vacuum pumps results in and up to 80% less noise.

Features as standard

- Universal double gripper system for separating of sections and single sheets without any adjustments

- Separate, shaftless servo drive for use as stand-alone or inline operation

- Upright, smooth product transfer in the transport channel supported by blowing air

- Reliable and non-marking separating of sections thanks to the 25° incline of the stations

- No spiral race element required for infeed into a perfect binder

- Integrated, patented vacuum technique Winjector

- Integrated terminal with graphic display and touch-screen function

- Motorized adjustment of the transport channel

- Control system for automatic run-up and run-down as standard

- Pulsing blowing air in front in the magazine ensure reliable processing of single sheets down to 70 g/m²

Technical data Sprinter e / s

| Mechanical speed, Inline | 1000 - 8000 cycles/h* | |

| Operation with criss-cross | 1000 - 5000 cycles/h* | |

| Product height | 105 - 370 mm | 4,13" - 14,57" |

| Product width | 75 - 320 mm | 2,95" - 12,60" |

| Transport channel width | 80 mm | 3,15" |

| Number of stations | 4 - 28* |

* depending on selected machine configuration

Technical data Sprinter eXL / sXL

| Mechanical speed, Inline | 1000 - 8000 cycles/h* | |

| Operation with criss-cross | 1000 - 5000 Cycles/h* | |

| Product height | 105 - 485 mm | 4,13" - 19,09" |

| Product width | 75 - 320 mm | 2,95" - 12,60" |

| Transport channel width | 80 mm | 3,15" |

| Number of stations | 4 - 32* |

* depending on selected machine configuration

Material range (for all models)

| Single sheets, depending on product | 70 g/m2 |

| For folded sections (pages) | 64 |

Editions

| Editions | Sprinter e/sXL | Sprinter s/eXL |

|---|---|---|

| Diagnosis terminal with touch-screen function | ||

| Speed indicator and product counter | ||

| Preselection of product counter | ||

| Automatic run-up and run-down | ||

| Shaftless drive and PLC-control | ||

| Mechanical miss- and double sheet control | ||

| Automatic caliper control ACC | ||

| Low level pre-warning in each magazine | ||

| Winjector vacuum technology | ||

| Motorized transport channel adjustment | ||

| Blowing air nozzles in the transport channel | ||

| Pulsing blow air in front gauges | ||

| Handfeeding station with 1 or 2 pockets | ||

| Criss-Cross delivery | ||

| Reject gate | ||

| Camera system Winspector | ||

| Winspector with barcode reading | ||

| Changeover to half drum speed | ||

| Transfer unit to perfect binder | ||

| Special grippers up to 12 mm thick products | ||

| Drive belts in the magazine | ||

| CE / ET sign |

Standard Option