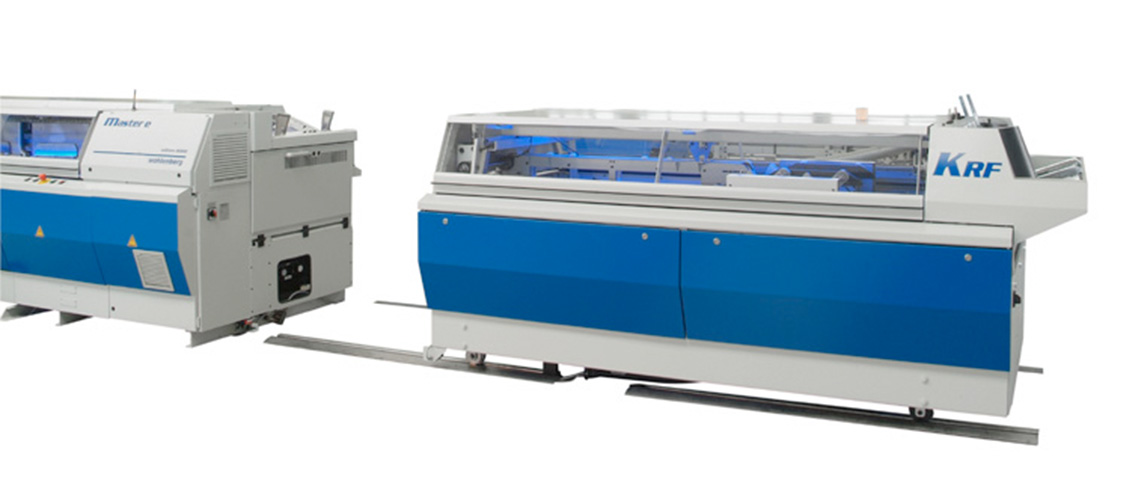

KRF

Gatefolded product in one pass

Products with gatefolded covers can be produced rationally and inline with the cover folder feeder. The full-surface scoring knives guarantee an excakt scoring of even the heaviest cover stock. Folding process via folding knives, shaped parts and pressing rollers. All essential format adjustments motorised via Navigator. The cover folder feeder is available on the inline or universal editions.

A visible sign of this new technology is, that the cover folding station KRF allows processing of open covers of more than 1000 mm.

10 teat positions in Winjector technology, a feed device in the bottom plate of the feeder and pulsating blown air ensure a safe and constant separation of the covers.

Features as standard

- Short setup time

- Corrections even during production

- Motorised adjustment of all main functions

- Cover feeder with Winjector Technology

- Device for back pressure release

- Non-contact double-sheet control with ultrasonic sensor

- Integration of KRF into the Navigator of the perfect binder

Technical data

| Mechanical speed | 1000 - 7000 cycles/h* | |

| Cover height | 140 - 490 mm | 5,51" - 19,29" |

| Cover width | 208 - 1002 mm | 8,19" - 39,45" |

| Cover weight | 200 - 400 g/m² | 7,87" - 15,75" |

* Net output is depending on material, the product type, glue technology, etc.